Articles By Our Members

Radio Frequency Interference (RFI) Suppression in Model Boats

by David Harrison, September 2005

Introduction

This article discusses the sources of Radio Frequency Interference (RFI)

in model boats, how this is propagated to sensitive electronics and suggests

several techniques for minimizing its effects. The information here comes

from common sense, sound electrical/electronic engineering practices, model

boat books and the practical experience of fellow model makers. I have just

gathered it all together in one place. Particular thanks is given to Ken

Huntington of our club for good information on this topic.

In model boats, there are several sources of radio frequency

interference. The most important one is the RFI generated by the main

electric propulsion motor(s). A secondary, less important, source is the

movement of metal surfaces (especially dissimilar metals) across each other.

A minor one, usually of no significance, is the ESC microcontroller (a small

microprocessor) and its surrounding circuitry (any digital circuitry has the

potential to generate RFI due to the switching current of the digital

signals).

Electric Motor Generated RFI

The information in this article relates to the usual brushed electric

motors used for model boat and submarine propulsion. This does NOT apply to

brushless motors.

Brushed motors generate RFI by two mechanisms:

- The commutator switching current to the armature windings causing sharp

current spikes in the supply leads.

- The commutator arcing (sparks) causing radiated RFI through the air.

Sharp current spikes are generated every time the commutator gaps pass

under the brushes due to the sudden inrush of current into its corresponding

armature winding. The current spikes, being of very short duration, contain

many high frequency energy components that can extend well into the hundreds

of MHz, depending on the speed of the motor, number of motor poles etc.

These current spikes can be propagated back into the R/C equipment by two

mechanisms.

- The current spikes will manifest themselves as voltage spikes at the

battery, and at any point along the length of the wire due to the non-zero

resistance and inductance of the wire. These voltages can find their way

directly back into the R/C receiver and servos by the receiver supply wires.

- The supply wires themselves will act as antennas radiating RF EMI

(ElectroMagnetic Interference) back to the receiver through the air.

Similarly, the arcing at the commutator can propagate directly through

the air to the R/C equipment. Arcing is caused by the abrupt switching of

current at the brush/commutator gaps and also by the generator effect of the

fast turning windings generating "back EMF" (Electro Motive Force - i.e.

voltage). Do you remember that the very first wireless transmitters had a

very large spark gap to generate the RF signal?!

As well as the receiver and servos containing sensitive electronics, the

speed controllers (ESCs) do as well, containing a microcontroller

Suppression Techniques

RFI suppression techniques target the two propagation mechanisms i.e.

conducted interference through the supply wires and direct radiation through

the air.

Reducing Conducted RFI through the Supply Leads

Suppression Capacitors

Solder a 0.1μF capacitor across the motor terminals and a 0.1μF

capacitor from each motor terminal to the motor can. The motor can will

likely not heat up well enough with a regular soldering iron to take the

solder well, so often some mechanical means of attaching the capacitor wires

must be found. The capacitors create a low impedance (i.e. AC "resistance")

to the high frequency RF signals, but no DC resistance. Do not use

capacitors much larger than 0.1μF since their charging and discharging

currents put an extra load on the ESC output transistors. Be sure to use

good high frequency capacitors such as ceramic. Never use electrolytic or

tantalum capacitors as these do not have good high frequency characteristics

and they are polarised (they have + and - leads and can only be connected

one way round). The voltage rating of the capacitors is usually not an

issue since commonly available ceramic capacitors are rated at about 50V.

Quite often the above capacitors are installed by modelers, but the

following tips will make them much more effective.

- Keep the capacitor leads as short as possible. If you have to compromise

between short motor can side versus brush connector side, always keep the

brush connector side as short as possible.

- Always connect the motor can(s) to the negative battery supply lead. If

you do not connect your motor can to anything other than the suppression

capacitors, then it will act as a big fat antenna radiating the RF

interference coupled into it by the capacitors! Exactly the opposite of

what you want!

- "Ground" the motor can(s) by connecting them to your propeller shaft

stuffing box (prop. shaft tube). Make sure the propeller end of the stuffing

box has a small area without paint to make contact with the pond water.

Although the pond is not a great electrical conductor, it does act as a weak

"ground plane," thus dissipating the can motor RF interference signals to

"ground".

If you make the -ve battery or ground connections suggested, keep

the wires as short as possible otherwise they may act as antennas

themselves.

A note about pond water:

Pure water is a weak conductor. Dissolved solids such as salt and other

acid or alkaline compounds greatly increase its conductivity due to free

ions making it a weak battery electrolyte. Thus sea water is a pretty good

conductor, relatively speaking.

Pond water is somewhere in between, but with all the gunk we find in it,

it is probably a better conductor than your average bathtub full of city

water. We all know that you stand the risk of electrocution if an

electrical appliance falls into the tub and you are in it!

Thus you can see that the pond surface acts somewhat as a ground plane.

If it were a great conductor, then R/C submarines would never work because

the R/F transmitter signal would never penetrate the surface.

Ferrite Beads

A further technique for reducing both conducted and radiated RFI is to

put ferrite beads on the motor supply leads as close to the motors as

possible. Both supply wires should go through one bead. Ferrite is a

non-metallic ferrous (iron) compound that greatly increases the magnetic

flux around and through it. The effect of placing them on the supply leads

is to increase their inductance, which acts as a "choke" to the RFI signals

in the wire. If the beads are large enough, it is even better to wind both

supply leads through and around the bead once to make a kind of elementary

transformer. In this way, the current spikes in one wire will cancel out

the current spikes in the other wire, since the current will be going in the

opposite direction.

Ferrite beads are often hard to find, especially in sizes large enough to

accommodate the heavy wire gauges (e.g. 12AWG) necessary for fast electric

motors.

Electronic surplus store are usually the best source for these. In

Ottawa you can try ADD Electronics, on Armstrong Avenue, near the Parkdale

market. The beads are often shaped like a short thick walled cylinder.

They cost about $1 each. The large bulges in computer monitor cables near

the monitor end also contain ferrite beads so if you have a useless monitor,

cut the cable open and see what you find. Alternatively, they can be

obtained from Digi-Key (ca.digikey.com) - part no.

240-2080-ND

for about a dollar. Shipping and handling charges apply though.

Transient Suppressors

Transient suppressors (also known as transient voltage suppressors or

transorbs) are like two series back to back zener diodes. Thus they are

bi-directional and will clamp voltage transients to their "zener" voltage,

e.g. 15V. They can be very effective in reducing RFI by connecting them

across the motor terminals (again with very short leads) in addition to the

capacitors. They are available in a variety of voltage and power ratings.

The voltage rating should be chosen to be just a little above your maximum

possible battery voltage (taking into account possible overcharging). Thus

for a 12V gel battery which can get up to about 14V when fully charged, a

15V rating is appropriate. If you are running 7.2V batteries, a rating of

9V is OK and for a 6V system use 7.5V. Again, these are somewhat hard to

find - Digi-Key has them e.g. part no.

P6KE15CALFCT-ND

for a 15V 600W device. Ken Huntington in our club sometimes has them on

hand.

Shared Ground and Power Wiring

Shared ground and power wiring is when two or more connections are made

to the -ve and +ve battery terminals at different locations along the supply

wires. Also a conducting loop can easily be formed if there are multiple

return paths in the wiring. If any part of the shared wire or loop carries

high motor currents, the resistance of the wire, although small, can create

small spiky voltage drops along the wire. If that same wire is shared by

electronic modules, then the supply voltage to that module becomes spiky as

well. Ideally, all connections to the battery should be made in a "star"

configuration so that wires are not shared between motors and electronics.

In practice this is difficult to achieve, especially when the typical BEC

(Battery Eliminator Circuit) in the speed controller is used to supply power

to the receiver. We usually use a BEC, if one is available, but that does

mean the receiver shares its ground line with the ESC supplying high

currents to the motors.

Example Photos

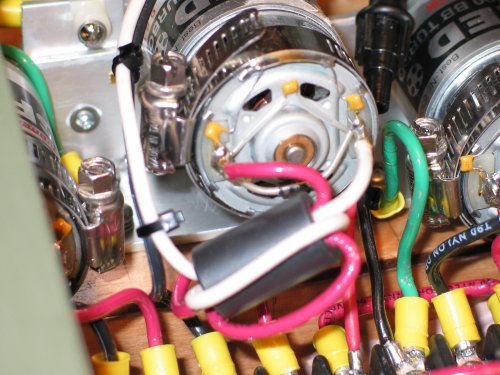

Photo 1 - motor connections:

Note the capacitors and ferrite bead. The transient suppressor can be

seen just below the motor end bearing. The hose clamp is used to clamp a

small piece of thin brass bar to the motor can. The capacitor wires are

soldered to the piece of brass, not the actual motor can.

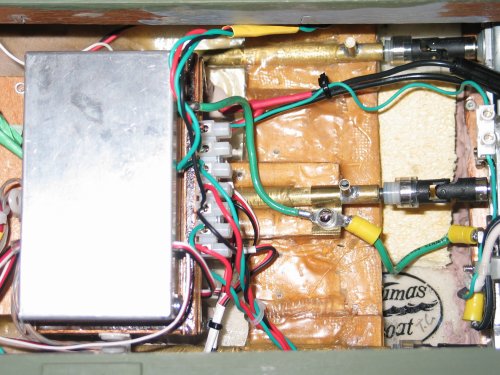

Photo 2 - Ground connections:

Note the aluminum receiver box and the brass clamp around the centre

propeller stuffing box. Also notice the SHORT thick green grounding wire

between the stuffing box and the receiver box and between the stuffing box

and the aluminum motor mounting plate.

Reducing the Effects of Radiated RFI

Radiated RFI can be reduced by keeping all possible radiating antennas,

i.e. motor supply leads, as short as possible. This also helps to reduce

the voltage loss due to series resistance, although this is usually

negligible if you use 12AWG wire.

The other obvious method of reducing the effects of radiated RFI are to

keep the sensitive electronics (receiver, servos, speed controllers) as far

away from the motors and their supply leads as possible. Obviously, in the

case of the ESCs, these cannot be kept too far away, otherwise the supply

leads will act as longer antennas. Generally keep the ESCs away from the

receiver (in the opposite direction away from the motors).

I choose to mount my receiver in a grounded aluminum box to reduce RFI

radiating directly into the receiver.

Also keep the receiver antenna wire as far away as possible from the

motors, their wires and the ESCs. If your motors are heavy duty, high

current types, then the majority of the antenna wire should be vertical to

get a better signal/noise ratio. This may present a problem in some scale

models, but modelers are usually quite ingenious. Use a mast, a scale

antenna, crane jib etc.

Model Submarines

The above information obviously pertains to model submarines even more

so, since space is usually very limited and the effects of loss of control

due to RFI are much more dramatic than with a surface vessel. Thus pay

particular attention to all the above techniques for RFI reduction.

Mounting Electronics

Although this is not directly related to RFI, all model electronics

should be mounted with a degree of vibration isolation. Model boats,

especially fast ones, have a considerable amount of mechanical vibration

inside the hull. Over a long period of time, this vibration can weaken soft

soldered joints, making them unreliable and even open circuit.

Thus mount your receiver in a bed of rubber or polyurethane foam inside

your receiver box. Always use the rubber grommets supplied with your servos

for their mounting and keep the servo bodies from touching adjacent

surfaces. For receiver box and ESC mounting I use self adhesive Velcro.

This may sound crude, but it provides a bit of vibration isolation and

usually the adhesive on the Velcro strips is quite aggressive, providing a

strong attachment.

David Harrison

|